How Does a 3 Phase Servo Motor Work

Oct 25, 2024|

Oct 25, 2024| View:382

View:382

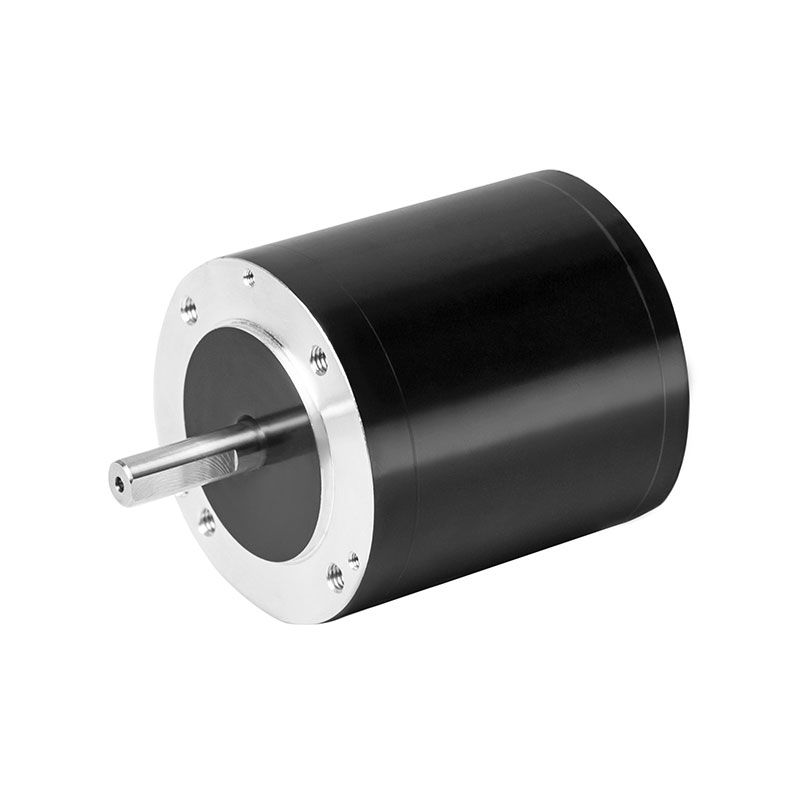

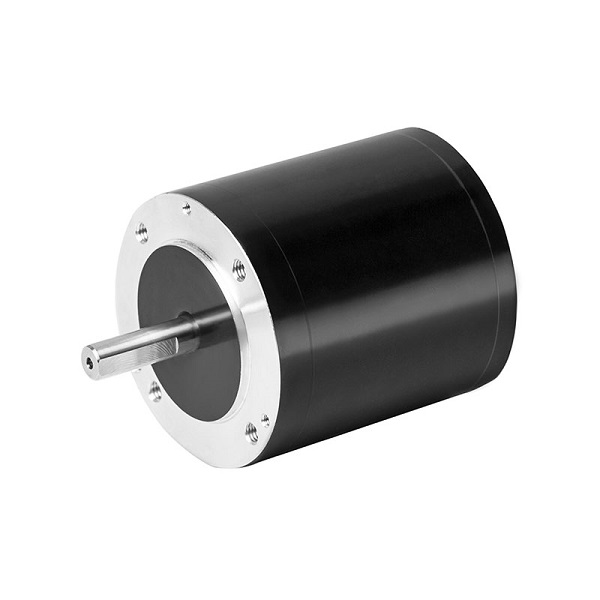

With the continuous development of industrial automation, motors play a crucial role in various fields. Among them, 3 phase servo motors have become the core components of many automation equipment due to their high precision, high reliability, and fast response. So, how does a 3 phase servo motor work?

Basic concepts

A 3 phase servo motor is a type of motor that can accurately control speed and position. Compared with ordinary motors, it has higher precision and faster response speed. A 3 phase servo motor usually consists of a motor body, an encoder, and a driver. Among them, the motor body is the core component for converting electrical energy into mechanical energy; the Encoder is used to provide feedback on the position and speed information of the motor. The driver precisely controls the motor based on the control signal and encoder feedback information.

Compared with other types of motors, 3 phase servo motors have the following characteristics:

High precision: capable of achieving precise position and speed control, with an accuracy of up to micrometer level.

High response speed: Short response time, able to quickly track changes in control signals.

High reliability: Adopting advanced control technology and high-quality materials, it has high reliability and stability.

Can achieve complex motion control: capable of implementing various complex motion controls, such as linear motion, circular motion, etc.

Working principle

The working principle of 3 phase servo motor is based on the law of electromagnetic induction and the theory of rotating magnetic field. The structure of a motor mainly includes two parts: a stator and a rotor. There are three sets of windings on the stator, each connected to a three-phase power supply. When a three-phase power supply is applied to the stator winding, a rotating magnetic field is generated. The rotor is equipped with permanent magnets or windings, and under the action of a rotating magnetic field, the rotor will rotate along with the rotating magnetic field.

How does a three-phase power supply generate a rotating magnetic field? When the phases of the three-phase power supply differ by 120 degrees in sequence, a rotating magnetic field will be generated in space after passing through the stator winding. The rotational speed of this rotating magnetic field is proportional to the frequency of the power supply and inversely proportional to the number of pole pairs of the motor. By controlling the frequency and voltage of the power supply, precise control of the motor speed can be achieved.

Control system

Encoders and drivers play a crucial role in the feedback control of 3 phase servo motors. The encoder is installed on the shaft of the motor and can provide real-time feedback on the position and speed information of the motor. The driver achieves precise control of the motor by adjusting its current and voltage based on control signals and encoder feedback information.

In feedback control, the driver continuously compares the difference between the control signal and the encoder feedback information and adjusts the motor output based on this difference. This feedback control mechanism enables the 3 phase servo motor to achieve high-precision position and speed control.

Application Fields

Three phase servo motors have a wide range of applications in the fields of industry and automation. The main applications include:

Numerical Control Machine Tool: Used to control the feed axis of the machine tool and achieve high-precision machining.

Robot: As the joint drive motor of the robot, it achieves precise motion control.

Automated production line: used to control the movement of various automated equipment and improve production efficiency and quality.

Printing equipment: used to control the paper conveying and printing drum movement of the printing machine, ensuring printing quality.

Advantages and disadvantages analysis

The advantages of 3 phase servo motors mainly include:

High precision: capable of achieving precise position and speed control, meeting the needs of high-precision machining and automated production.

High response speed: Short response time, able to quickly track changes in control signals and improve the dynamic performance of equipment.

High reliability: Adopting advanced control technology and high-quality materials, it has high reliability and stability, reducing equipment maintenance costs.

Capable of achieving complex motion control: capable of implementing various complex motion controls to meet the needs of different application scenarios.

However, 3 phase servo motors also have some potential drawbacks:

High cost: Compared to ordinary motors, the price of 3 phase servo motors is higher, which increases the cost of the equipment.

High environmental requirements: It needs to be used in a relatively clean and dry environment, otherwise it may affect the performance and lifespan of the motor.

Complex control: requires professional drivers and control systems and demands high technical proficiency from operators.

Future Trends

With the continuous advancement of technology, the technology of 3 phase servo motors is also constantly developing. In the future, the development direction of 3 phase servo motors mainly includes:Higher precision and speed: With the continuous improvement of machining accuracy and production efficiency, the requirements for precision and speed of 3 phase servo motors will also become increasingly high.

Intelligent control: Combining artificial intelligence and machine learning technology to achieve more intelligent control and improve the performance and adaptability of motors.

Miniaturization and lightweighting: With the trend of miniaturization and lightweighting of equipment, 3 phase servo motors will also develop towards miniaturization and lightweighting.

Energy saving and environmental protection: Using more energy-efficient and environmentally friendly materials and technologies to reduce the energy consumption of motors and their impact on the environment.

In summary, 3 phase servo motors are high-precision, high-response speed, and high-reliability motors that have a wide range of applications in the industrial and automation fields. By understanding the basic concepts, working principles, control systems, application fields, advantages and disadvantages analysis, and future trends of 3 phase servo motors, we can better comprehend and apply this advanced motor technology. If you need high-quality China servo motors, Baolong is your most reliable servo motor supplier. We will provide you with high-quality products and professional services to meet your various needs.