What is the difference between an inrunner and outrunner motor?

Jun 11, 2025|

Jun 11, 2025| View:23

View:23In fields such as drones, power tools, and industrial automation, brushless DC motors (BLDC Motors) have become the mainstream power source due to their high efficiency, long service life, and excellent speed regulation performance. However, when selecting a brushless motor, a fundamental yet critical question arises: What is the difference between an inrunner and outrunner motor? The two main structural types—Inrunner Motors and Outrunner Motors—exhibit significant differences in design and performance, directly influencing their application effects. This article clearly disassembles the core distinctions between the two to help you make precise selections.

Core Structural Difference: What Rotates?

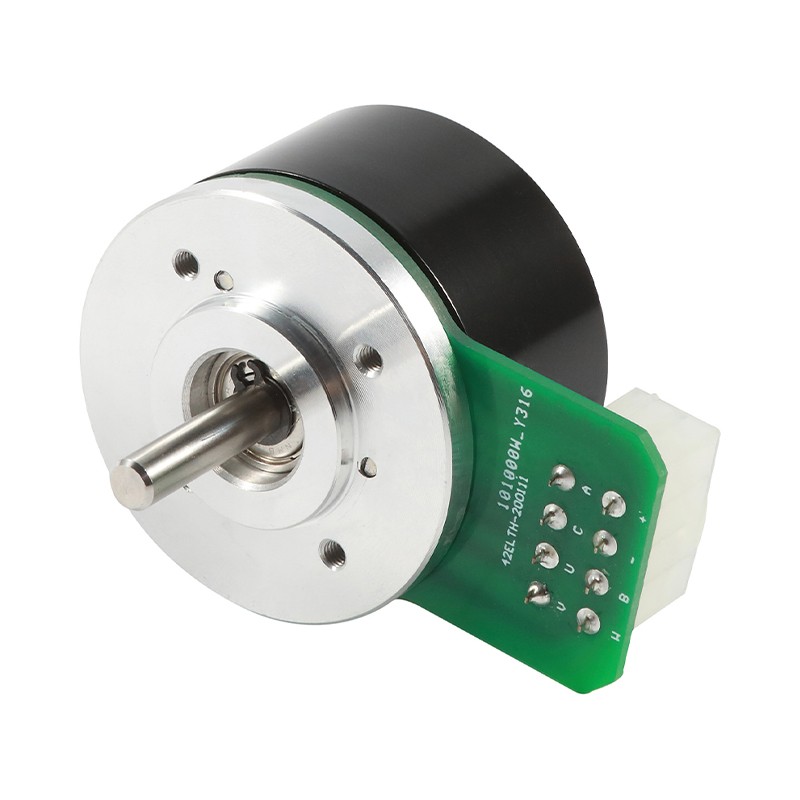

Inrunner Motor

- Rotor Position: The magnet (rotor) is located at the central interior of the motor.

- Stator Position: The coil winding (stator) is fixed on the outer casing, surrounding the inner rotor.

- Rotating Part: The central shaft (solidly connected to the rotor) serves as the motor's output shaft, which rotates and transmits torque.

- Appearance: Typically appears as a cylinder. The outer casing (stator) is stationary, and only the central shaft rotates. The casing has a relatively small diameter and may be longer in length.

Outrunner Motor / Outrunner BLDC Motor

- Rotor Position: The magnet (rotor) is mounted on the motor's outer casing.

- Stator Position: The coil winding (stator) is fixed on a central bracket inside the motor.

- Rotating Part: The entire outer casing (solidly connected to the rotor) is the motor's output component, rotating around the fixed inner stator. The output shaft is usually directly connected to or integrated with this rotating casing.

- Appearance: Often resembles a "cup" or "can," with the outer wall (rotor casing) rotating and the inner center (stator) remaining fixed. The casing typically has a larger diameter and is relatively flat (shorter axial length).

Performance Comparison: Torque, Speed & Efficiency

Torque Output Capability

- Outrunner BLDC Motor Advantage: As the magnet (rotor) is mounted on a larger outer ring, the lever arm (radius) is longer. According to the principle that torque = force × radius, Outrunners generate greater torque under the same electromagnetic force. They are often synonymous with high-torque, low-speed motors.

- Inrunner Motor Feature: The magnet is located at a smaller central radius with a shorter lever arm. Under the same electromagnetic force and size, its torque output is typically lower than that of an equivalent Outrunner. However, they are more easily designed as high rpm brushless motors (high-speed brushless motors).

Speed Capability

- Inrunner Motor Advantage: With a rotor (rotating part) of small mass, diameter, and low moment of inertia, it easily achieves very high speeds (high RPM). It is the preferred choice for high rpm brushless motor applications, such as high-speed electric spindles, turbochargers, and certain drone propellers (driven by a speed reducer).

- Outrunner Motor Limitation: The rotating component is the entire outer casing (including the magnet), which has large mass, diameter, and high moment of inertia. Limited by mechanical strength and centrifugal force, its maximum speed is usually lower than that of the same-sized Inrunner. It is more suitable for medium-low speed, high-torque applications.

Efficiency & Cooling

- Cooling: The stator coils of an Outrunner BLDC Motor are located at the center, surrounded by the rotating casing, resulting in relatively poor heat dissipation conditions. Especially during continuous high-power operation, heat is difficult to dissipate, which may become a limiting factor. In contrast, the stator (heat source) of an Inrunner is located on the outer casing, making it easier to dissipate heat through the casing (e.g., by adding heat sinks or air cooling).

- Efficiency: Within their respective optimal speed ranges (Outrunners at low-medium speeds, Inrunners at medium-high speeds), both can achieve high efficiency. However, efficiency decreases when operating outside the designed speed range.

Power Density

- Outrunner Motor: In applications requiring high torque and low/medium speeds (such as direct-drive propellers for drones or hub motors for electric scooters), it typically has a higher torque density due to its structure's efficient space utilization for torque generation.

- Inrunner Motor: In high-speed applications, it achieves higher power density.

Natural Fit for Different Applications

Typical Applications of Outrunner BLDC Motor

- Drones/Multirotors: Directly driving large propellers is its most classic application. The high-torque characteristic enables efficient driving of large blades without a speed reducer, simplifying the structure, reducing weight, and improving reliability.

- Hub Motors for E-bikes/E-scooters/E-skateboards: The Outrunner structure is naturally suitable for integration into the wheel interior to directly drive wheel rotation.

- RC Planes/Cars/Boats: Especially in scenarios requiring high thrust/torque at moderate speeds.

- Fans/Blowers: Fan blades can be directly mounted on the Outrunner.

- Industrial equipment requiring high starting torque and low-speed operation.

Typical Applications of Inrunner Motor

- High-speed applications: CNC spindles, high-speed grinders, centrifuges, turbo molecular pumps, drones/aeromodels (achieving high speeds via speed reducers for small blades), and certain power tools (such as hand drills and grinders, usually with planetary gear reducers).

- Continuous high-power applications requiring good heat dissipation.

- Axially narrow spaces with limited room but high power density requirements.

Matching the Best Solution for Your Power Needs: Choose a Professional Partner

Understanding what is the difference between an inrunner and outrunner motor is the first step in selecting a brushless motor. The Outrunner BLDC Motor, with its large-diameter rotor design, is inherently adept at providing high-torque, medium-low speed power output, making it the ideal core for direct-drive drones and hub drives. The Inrunner Motor, with its low-moment-of-inertia central rotor, more easily achieves high speeds (High RPM), satisfying applications with extreme speed requirements. Neither is absolutely superior; the key lies in precise matching with application needs.

As a professional brushless motor supplier with deep expertise in motor technology, BAOLONG provides high-performance Inrunner and Outrunner brushless motor solutions. We thoroughly understand the design essence and performance boundaries of different structural motors. BAOLONG's Outrunner BLDC Motor series uses optimized magnetic circuit designs and high-quality materials to ensure efficiency and reliability under high torque. Our high rpm brushless motor product line focuses on precise dynamic balancing and heat dissipation designs to ensure smooth and durable high-speed operation. Whether for drones pursuing strong thrust or precision equipment requiring extreme speeds, BAOLONG delivers matched core motor power.

Choose BAOLONG to inject precise power into your innovative applications. With a rich product line, deep technical accumulation, and reliable quality, we are committed to being your trusted brushless motor partner. Contact BAOLONG today to obtain professional selection advice and customized motor solutions, driving your success!