- Product Specifications

- Quality Assurance

- Application and Processing

- Our Services

Product Description

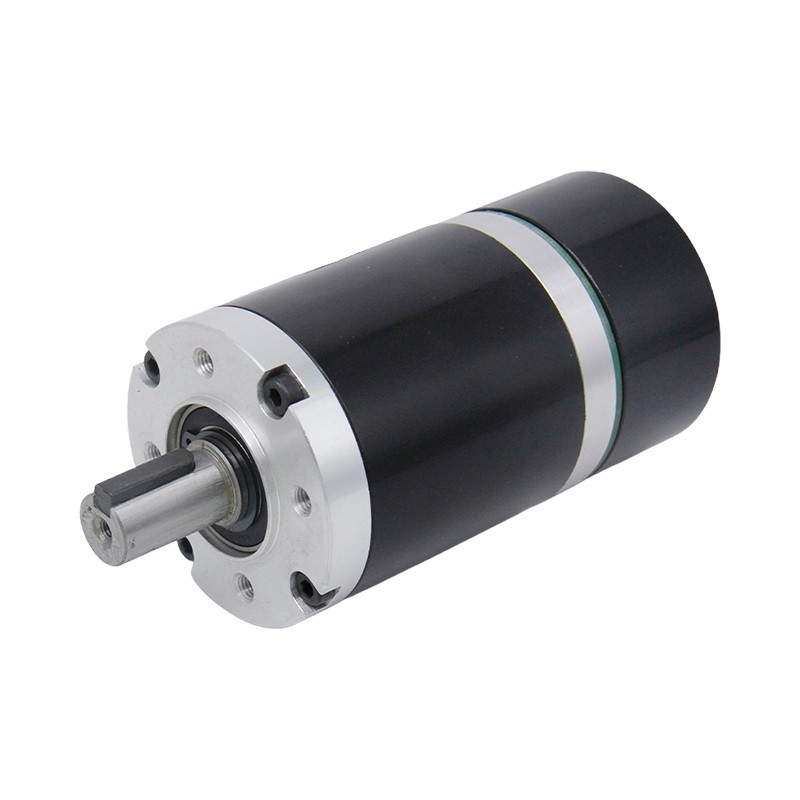

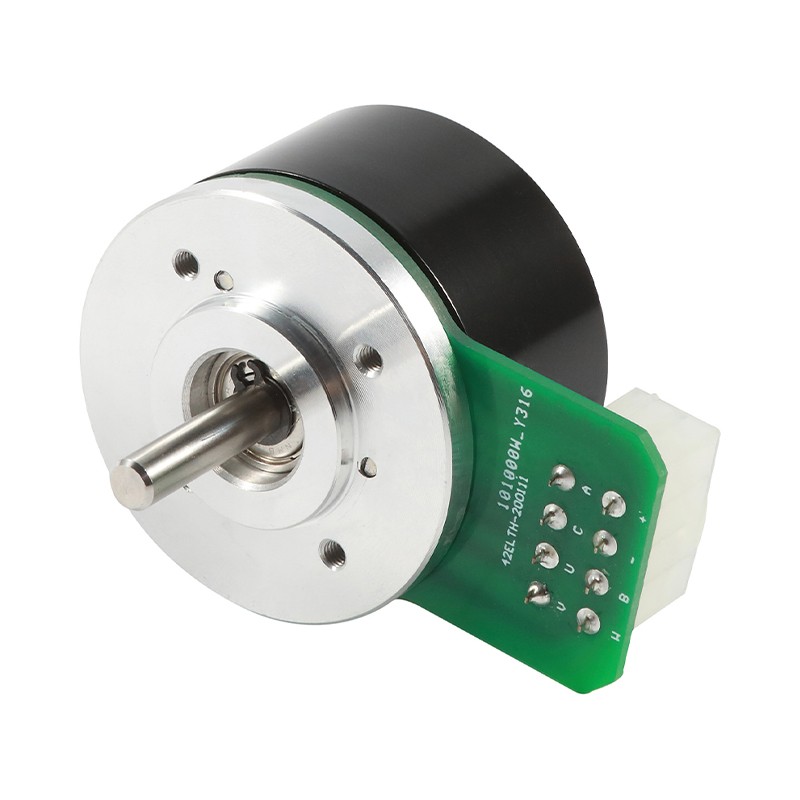

60PER-60EL Outer Rotor Brushless Motor inside and a much higher moment of inertia of the rotor.so the speed slower than inner rotor motor, which can be used to directly drive the load.

The rotor of bldc motor is an essential component in a brushless motor, including bldc rotor. It plays a crucial role in converting electrical energy into mechanical motion. The rotor of bldc motor is typically a rotating part of the motor that contains permanent magnets or electromagnets. As the motor receives electrical signals, the magnetic field generated by the rotor interacts with the stator's magnetic field, resulting in the rotation of the rotor and the motor's output shaft.

The term "rotor brushless motor" refers to a brushless motor in general, emphasizing the significance of the rotor in the motor's operation. The rotor is responsible for generating the rotating magnetic field that interacts with the stator's stationary magnetic field, enabling the motor to produce torque and rotational motion.

Similarly, "brushless motor rotor" and "bldc rotor" refer to the rotor component specifically in a brushless motor. These terms highlight the importance of the rotor in the context of brushless motor technology.

Electrical Specifications

| Motor Model | 60ELTH244530 | 60ELTH246030 | 60ELTH249030 |

| Rated Voltage (VDC) | 24 | 24 | 24 |

| Rated Speed (Rpm) | 3000 | 3000 | 3000 |

| Rated Torque (N.m) | 0.15 | 0.3 | 0.45 |

| Rated Power (W) | 45 | 60 | 90 |

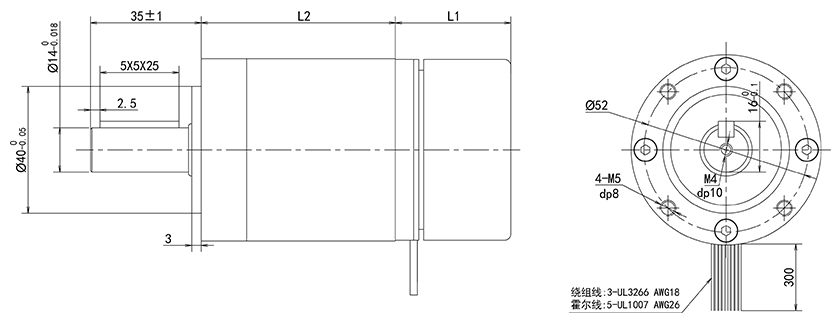

| Length (mm) | 29.3 | 34.3 | 39.3 |

Gearbox Electrical Specifications

| Reducer Series | 1 | 2 |

| Transmission efficiency | 96% | 94% |

| Max radial load | 580N | 580N |

| Max axial load | 340N | 340N |

| Transmission torque (N.m) | 28 | 20 | 10 | 30 | 30 | 32 | 30 | 30 | 25 | 25 | 20 |

| Reduction Ratio | 5 | 7 | 10 | 16 | 20 | 25 | 28 | 35 | 40 | 50 | 70 |

| Length (mm) | 38.3 | 52 |

*Note: We can manufacture products according to customer's requirements.

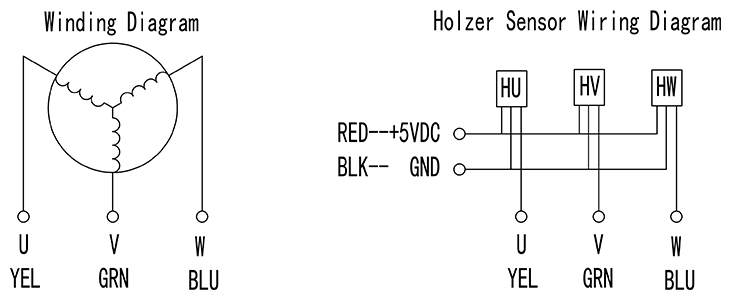

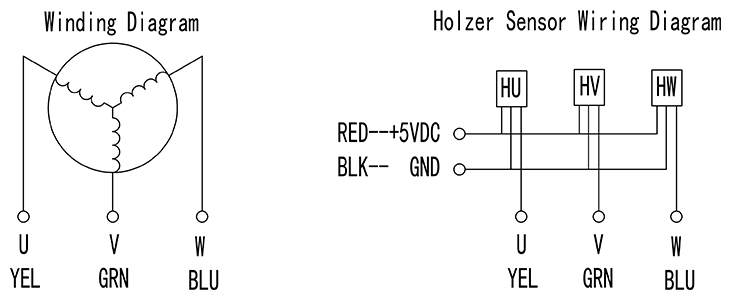

Wiring Diagram

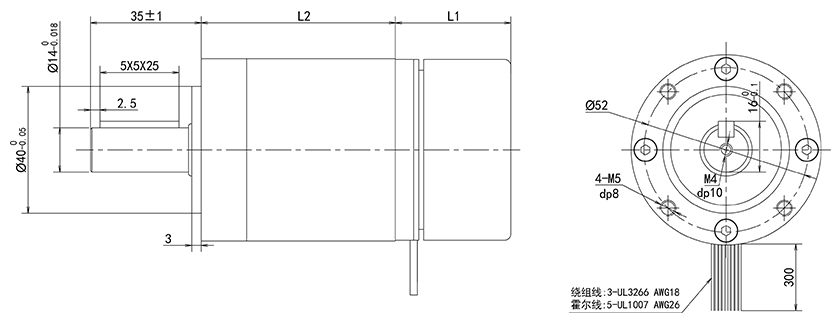

Dimensions(Unit: mm)

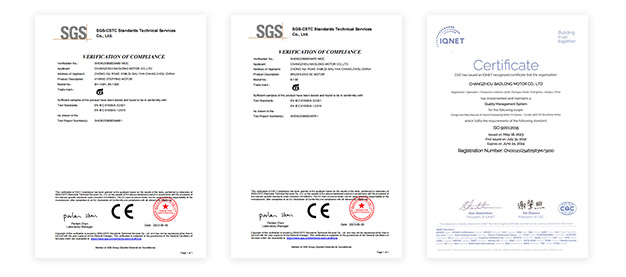

How Does Baolong Ensure Product Quality?

Through more professional technical support andservices to help them create sustainable value, win the trust and respect of customers home and abroad.During the past 20 years since establishment, our company has focused on the technica team building, constantly improving product quality.

Strict production process control

Carefully planning and controlling the production process of brushless motors to ensure that each step complies with standards and specifications. Using advanced production equipment and technology to improve production efficiency and product consistency.

Establishing a comprehensive quality inspection and testing system, including inspections of raw materials, components, and final products, among other stages. Using appropriate testing equipment and methods to ensure that the products meet the specified technical specifications and performance requirements.

Sound quality inspection and testing

Comprehensive product validation and certification

Conducting comprehensive validation and certification of brushless motor products to ensure compliance with international and industry standards. This may include electrical performance testing, temperature and humidity testing, durability testing, and so on.

Establishing a sound after-sales service system to promptly address customer quality issues and complaints. Analyzing and improving product quality issues to prevent similar problems from recurring and providing customers with satisfactory solutions.

Establishing an after-sales service system

Ordering Process

Analysis Design

Confirm Drawings

Make Rotor and Stator

Assembly

Test Inspection

Packaging and Delivery

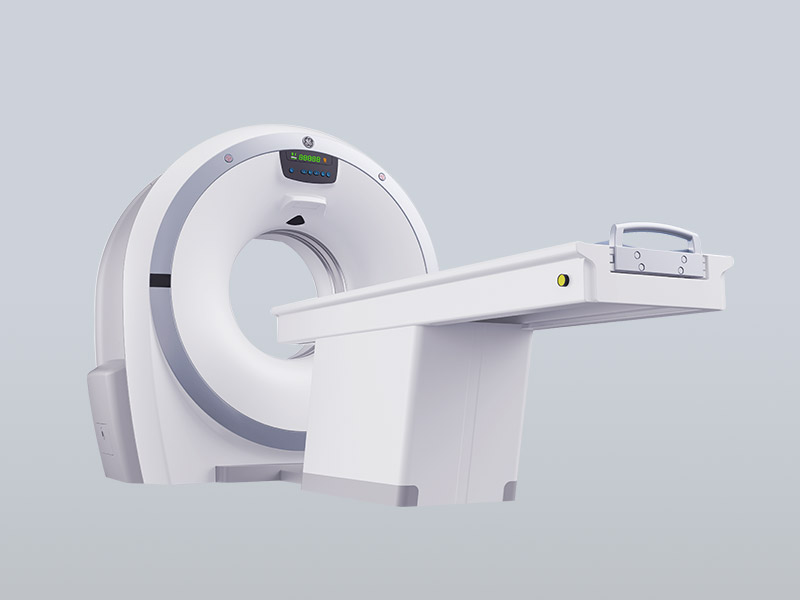

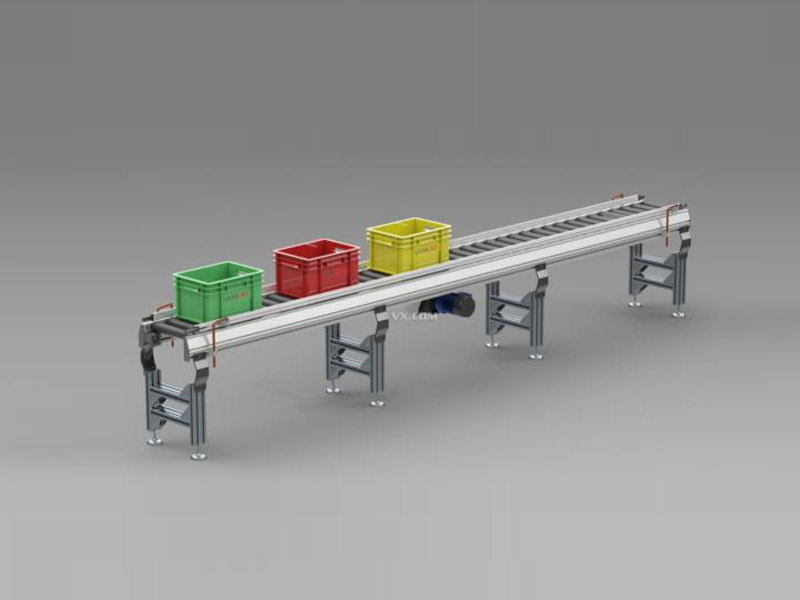

Product Application

Baolong products are widely used in textile machinery, medical equipment, communication equipment, security systems, vehicle manufacturing, as well as robotics, logistics warehousing, industrial automation and other industries. Baolong's R&D team is always ready to meet the increasingly differentiated needs of the market.

Electric Medical Beds

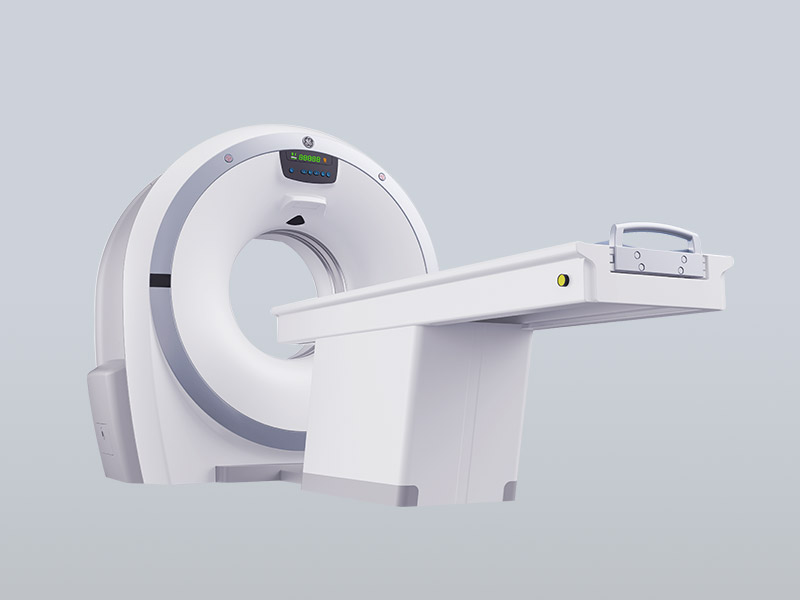

CT Machines

Blood Analyser

Ticket Card Recycling

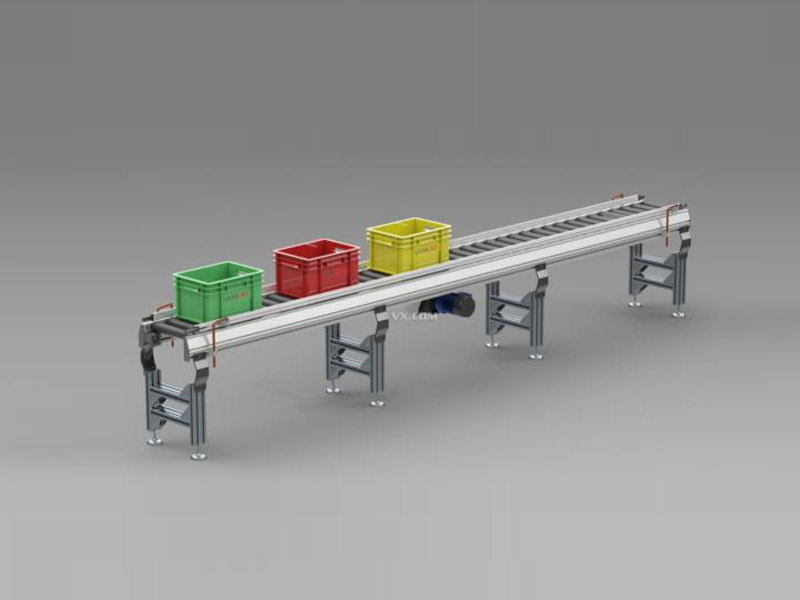

Transmission Equipment

Coffee Machines

Logistics Sorting

AGV

Why do we use Brushless Motor?

Brushless motors offer high performance, good speed-torque characteristics, long life and low maintenance costs, making them ideal for manufacturing applications.

Who is Baolong Motor?

Changzhou Baolong Motor Co.,Ltd. is a high-tech enterprise specializing in the development, design, production and marketing of stepper motors.Founded in 2004, we adhere to the "innovative product, excellentquality, customer-centered" purpose, focusing on the micro-special motor industry, to provide automationequipment manufacturers with quality motor products. Through more professional technical support andservices to help them create sustainable value, win the trust and respect of customers home and abroad.During the past 20 years since establishment, our company has focused on the technica team building, constantly improving product quality. With a profound technical background and rich experience in motorindustry, we have successively developed stepping servo motor, stepping linear motor,motor driver,DCbrushless motor,AC servo motor, gear box and other products, which are widely used in textile machinery,medical equipment, communications equipment, security systems, vehicle manufacturing, as well as robots,logistics warehousing, industrial automation and other industries.

Why Baolong Is Trusted By 1000+ Global Partners?

Own FactoryWe have our own factory with complete molds and a complete set of production processes.

Production EnvironmentOur production facilities prioritize high standards and environmental sustainability.

Pay Attention to Product QualityWe manufacture all the products of excellent quality and we can always meet the design as customers required.

Free SupportProvide fast and timely delivery, and can answer your questions 24 hours a day.

Language

Language Language

Language